Recycling of automotive parts

Recycling of old vehicles and their parts is a traditional activity that has been practiced for many years in our country. In addition to the economic benefits for the processing industry, the collection and dismantling of end-of-life vehicles, hereinafter referred to as ELVs, leads to rethinking of the path of waste in modern society – from blocking the pavements and streets with improperly parked abandoned motor vehicles to provision of raw materials and transition to a circular economy.

Considering the industrialization and globalization, it is time to rethink our attitude towards nature and the impact of human activities on the quality of the environment and the depletion of natural resources. The current period is characterized by a shift from consumer behavior and promotion of consumption to the policy of extending the life cycle of products. In practice, this means reducing the waste to a minimum by stimulating the reuse of goods and increasing the amount of recycled materials.

Achieving this result wouldn’t be possible onlythrough the goodwill of society. This led to the introduction of legislative requirements related to waste management, first at European level, and subsequently in Bulgaria.

Regarding motor vehicle waste, the normative documents are as follows:

- Directive 2000/53/ЕC of the European Parliament and of the Councilfrom September 18,2000 regarding end-of-life vehicles– the directive wasadopted in2000 and has been amended several times to the present moment;

- Regulation on the end-of-life motor vehicles– adopted in January 2013, last amendments in July This is the normative document in force for the territory of Republic of Bulgaria, which includes all amendments of the European directive.

The adoption of these documents led to a complete change in the process of organization and financing of the activities related to end-of-life vehicles. The main focus is the change of responsibilities (introduction of the principle“extended responsibility of the manufacturer”),namely – assignment of obligations to the manufacturers of motor vehicles and to the persons who place them on the market for the first timeon the territory of a given European country.These are the subjects that are required to organizethe collection and subsequent treatment of the waste that forms after we decide that the car that we have used is no longer needed.

Also, in the context of the growing awareness of the need to take real actions to protect the environment, reduce the consumption of natural resources, prevent wasteaccumulation and extend the life cycle of products, quantitative targets for reuse,recovery and recycling of end-of-life motor vehicles (ELVs) have been introduced. Depending on the category of therespective vehicle (L, M1, M2, :M3, N1, N2, N3), the targets are as follows:

- Reuse and recovery: 95 – 96% of theELVsweight;

- Reuse and recycling: 85 – 94 % of theELVs

Another essential requirement is that activities related to ELVs can be performed only after obtaining authorization from a competent environmental protection authority. In order to do so, the persons intending tocollect, transport or treat ELVsshould submit an application and provide information to prove that they are capable to execute the desired activities in a manner that ensures compliance with the specific requirements and that won’t lead to pollution of the environmental components.

The performance of the activities can start after the issuance of relevant documents authorizing the activity in accordance with the Waste Management Act:

- For collection and transportation of ELVs– registration document;

- For storage and dismantling of ELVs– permit for a specific site.

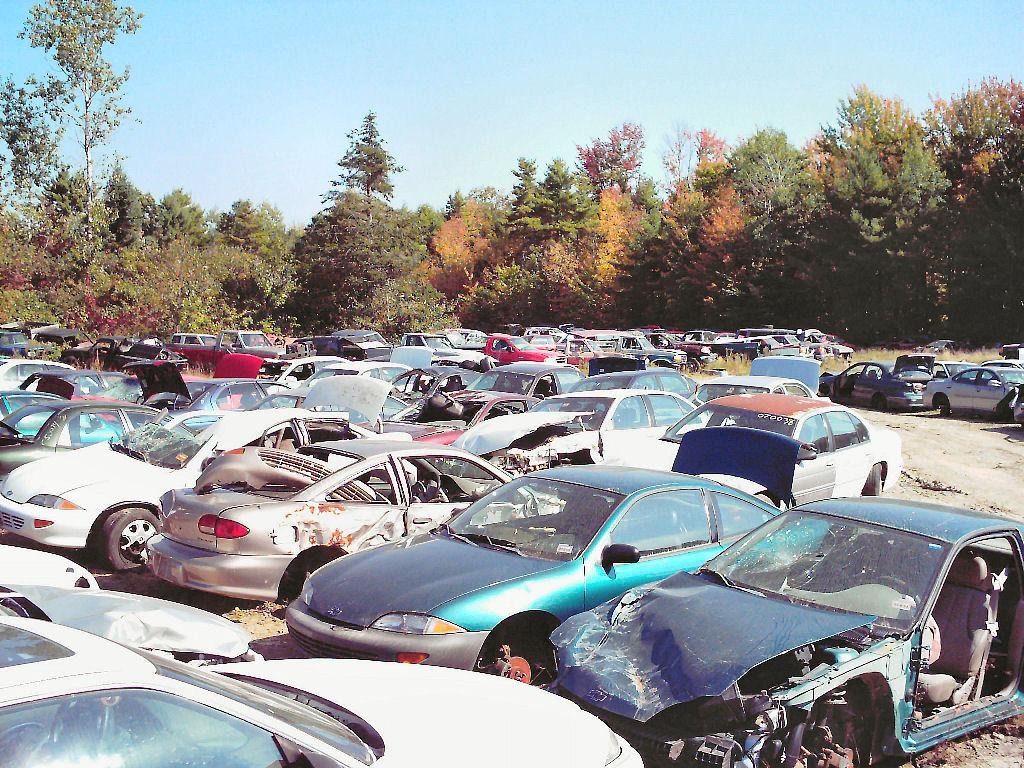

What happens to our vehicle once we have decided that we no longer need it and we have found an authorized companyto take it and to issue us a document required to de-register the vehicle by Traffic Police?

Our car is transported to a storage site or to a dismantling center where recycling preparations begin.

As specified above, the main goal is to achieve the highest possible degree of reuse, recovery and recycling of the parts, components and materials from which the vehicle is produced. Of course, the quantitative targets as a percentage of the weight of the vehicle must necessarily be achieved.

In view of this, one of the first steps after arrival of the ELVs at the dismantling center includes a detailed inspection of the car in order to identify parts that could be reused.

Dismantling

Thereafter, the dismantling of the vehicle begins, as the term that is used is „dismantling“and it includes the following operations:

- Removal of liquids and materials and components containing dangerous substances:

- – separation of the lead accumulator and the liquefied gas tanks;- separation and neutralization of potentially explosive components(includingairbags);- drainage of fuel andother working fluids (for example, motor, transmission and hydraulic oils, antifreeze, braking fluid, liquid of the wipers, refrigerate agents of the air conditioning installation);

– removal of components containing mercury.

- Removal of materials and components in order to facilitate recycling:

- Removal of oil filters and catalysts;

- Removal of tires;

- Removal of windows;

- Removal of bumper and armor panels;

- Removal of metal components containing non-ferrous metals (aluminum, copper);

- Removal of seats and so on.

After drainage of all liquids and separation of the abovementioned parts and components, the corpus of the car can be process in the following ways:

- Pressing and cutting into smaller pieces, or

- Shredding.

The described dismantling operations of ELVs can be performed in different ways: by manual operations or with the help of automated systems.

Draining liquids from ELVs

- Removal of materials and components in order to facilitate recycling:

|

|

Liquid drainage station for ELVs

The main equipment of the station for drainage of liquids from ELVs consists of ramp and pneumatic sets for waste fluid suction. The ramp for the vehicle includes stairs and working platform. It allows optimal access to the bottom and top of the car.It is equipped with a protective floorintended to collect potential spills of liquids.

The vehicle can be positioned with the help of a forklift or the ramp is equipped with a lifting device. The operations related to drainage of working liquids from the car are automated,as the facility is equipped with several pneumatic sets for the different types of fluids, and it includes pneumatic suction pumps, suctiondrills with various diameters and connecting hosesto collecting fuel tanks (gas, diesel) and for the other working fuels (motor oil, transmission oil, hydraulic oil, washing fluids for the windscreen, coolant,braking fluid, antifreeze).

Compression of dismantled ELVs to reduce the volume or shredding

|

|

|

| ELVs pressing | Shredding of ELVs andseparation of materials | |

Waste resulting from the dismantling consisting of separate parts and materials of the end-of-life motor vehicles, is subject to further processingfor the separation of parts into reusable, recyclable and non-recyclable.

- The separated parts from the vehicles that can be reused are provided toacar repair shops for recovery(repair and improvement of their appearance), then a specific document is issued – declarationof their delivery. The parts that are reused most often: hydraulic pumps, hydraulic cylinders, hydraulic and mechanical strips,steering rods, hinges, terminals, bearers, lateral bracing, ball pins, universal joints, joints and half-axles. In some cases is possible to reuse an engine after performing the necessary repair and recovery activities.

- Materials separated from ELVs that are recyclable: ferrous and non-ferrous metals, oils,oil filters, accumulators, tires, glass and some types of plastics).Recycling is performed in specialized installations that use the raw material resource of the respective material (the so-called material recovery of waste) for the production of similar products.

Separated ferrous metals in the process of old cars dismantling are a major source of raw materials for the steel industry. Statistical data show that ferrous metals account for79 up to 84 % of the weight of the vehicles. Considering the fact that upon metal recycling is used about 74% less energythan in the production of steel from natural resources, we can make the conclusion with regard to the positive economic effect of ELVs recycling. And the benefit related to environmental protection is indisputable – waste metalsreplace the use of ore, the extraction and processing of which is related to a number of negative effects.

Similar is the situation with regard to the economic and environmental effects of recycling of non-ferrous metals and lead accumulators that are separated from the old vehicles, which replace natural raw materials in the technological processes of production of copper, aluminum, lead. With regard to the lead accumulators, a full recycling cycle is used– i.e. the recycling doesn’t end with the production of lead and lead alloys, but it continues to the production of goods of the same kind – new accumulator batteries.

There is a rubber granulate, metallic fraction and textile residue upon recycling of tires. The technological operations includeremoval of the cord from the walls of the tires, cutting and shredding of the tires, separation of the resulting fractions by a metal and textile separator.

Rubber plates and floorings can be produced from the rubber granulate, or it can be used as a filler in different technological processes. Another method of recycling of tiresis the pyrolisis, as the obtained products are pyrolytic liquid fuel, solid residues containing carbon and pyrolyticgas, which is used in the technological process. Also, tires can be burned in cement kilns.

The drained oils from the cars are regenerated by various technologies, as one of the most modern is the vacuum distillation. The first step in recycling of oil filters is their centrifugation to separate the oil. Subsequently, the metal fraction is transferred for melting and the oil is regenerated.

The recycling of windows of vehicles is gaining popularity in recent years– in the production of bricks, as fillers for construction materials and so on.