Types of ferrous metals – which are they and how to recycle them?

Which are the ferrous metals?

The division of metals into two groups – ferrous and non–ferrous metals – has been established historically. The iron and all its alloys are belong to the ferrous metals. Provisionally, it is accepted to also conceder manganese and chromium, which are incorporated into the iron alloys, as ferrous metals. All other metals are united under the common name – non-ferrous metals.

The main division of ferrous metals is between steel and cast iron, both of which are an iron alloy with carbon. The main difference is the percentage of carbon in the alloys. If the carbon content is up to 2% we talk about steel and if the content is over 2% we talk about cast iron.

Although the difference is small, it leads to significant differences in the properties of the two alloys. Cast iron is brittle and can not be subjected to processes that are used in the production of steel products — pulling, forging, etc., and is poured into certain shapes. That’s why you can find it in a variety of household and industrial castings, from manhole covers to machines weighing tones.

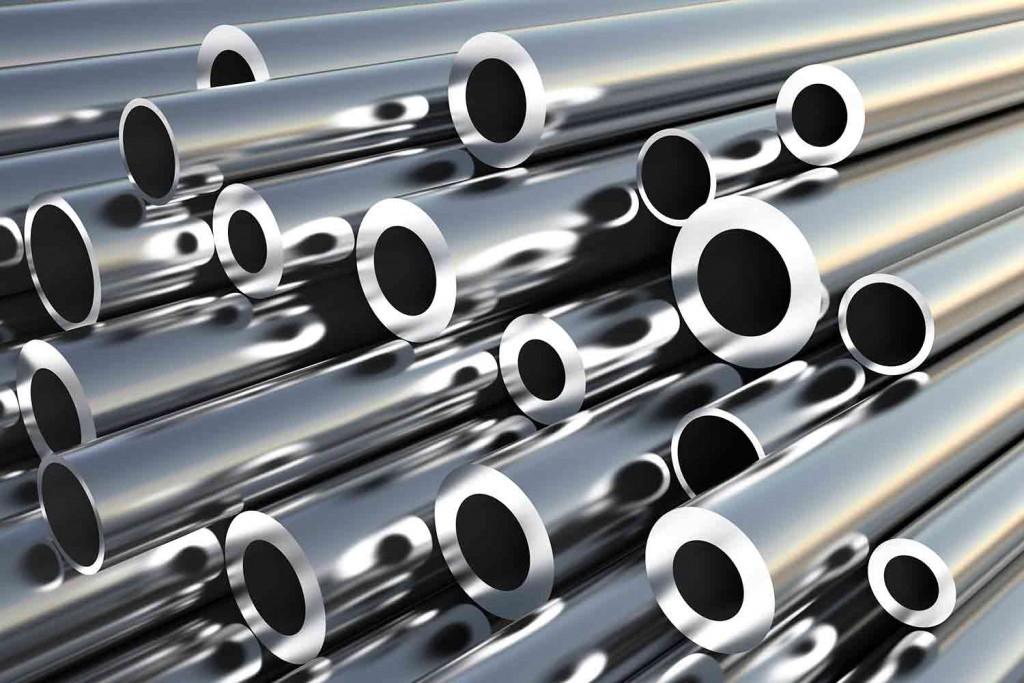

Steel is formed by oxidizing which leads to the separation of excess carbon and, in addition to the needs of production, it is enriched with various alloys. Steel is more advantageous for obtaining a variety of products thanks to its composition and properties.

Importance of ferrous metals in the human way of life

All kinds of ferrous metals have become an integral part of our lives thanks to their properties — mechanical strength, hardness, malleability, electrical conductivity, wear resistance and others. It is important that the properties of the types of ferrous metals can be modified by humans according to their needs in the process of their production.

By adding additional components — metals or non-metals, we are able to produce types of ferrous metals according to our needs. The type and amount of additions are carefully selected to achieve certain properties. Indicative of this is manganese steel. For example, increasing manganese content increases wear resistance, improves the mechanical properties of the steel by combining high plasticity and strength.

Chain track shoes for tractors and other track-chained machines, cladding for mills, crushing and cladding plates for crushers and other machinery are produced from used in the mining, coal output and cement industries highly alloyed manganese steel.

Given its properties, steel and its end products are classified according to many different criteria. For example, we can find classifications based on the carbon content, the content of the alloying additives, the mechanical properties (the strength), the purpose, the chemical composition, according to the production technology, depending on the surface (smooth, ribbed, sheet) and so on. Every day we encounter all types of ferrous metals. Steel is most common in construction, machine building, car manufacturing.

Cast iron is mainly used to make castings, which are in turn used in machine building and construction. Companies specializing in cast iron castings produce castings for heating appliances (fireplaces and stoves), drums for trucks and trailers, castings for the electric hoist and machine building, drainage grids, manhole covers and siphons, etc.

How to recycle ferrous metals

Recycling of ferrous metals represents their production through processing the waste from them — unnecessary pieces, machines, building materials and steel and cast iron household waste. Today, although ferrous metals’ production from iron ore is predominant worldwide, the more modern and environmentally friendly method is the production of ferrous metals through their recycling.

For the purpose of recycling of the types of ferrous metals it is necessary that the waste is collected, transported, sorted, prepared and delivered to the steelworks. Given the volume and weight of ferrous metals waste, these activities are labour-consuming and costly. Financial resources, technical equipment and good logistics are needed In order to perform them with quality.

Recycling of steel

As the most common types of ferrous metals, steel waste is recycled to the most. Recycling steel saves a lot of energy, natural resources and reduces harmful emissions to the atmosphere as a result of ore production.

About 60% less energy is required to produce steel from recycled materials than its production from iron. The steel has a 50% recyclable element and can be recycled repeatedly without changing its quality and strength.

For the recycling of steel, the so called electric arc furnaces. Waste ferrous metals, which we call “scrap” in short, are classified by types and, if necessary, go through further processing — cutting, shredding, sorting.

After sorting, the scrap is transported to electric arc furnaces. By means of high-capacity cranes, the scrap is emptied into the furnaces. This is followed by a scrap melting process, which is heated to about 1,650 degrees Celsius with the help of the electrodes. The molten scrap is poured into a teeming ladle, after which the molten metal goes into the furnace for further processing and produces the final chemical composition of the given steel grade.

Ready-to-use liquid steel is fed to steel rackers, the so called machines for continuous ladling of blanks. They produce semi-finished products — slabs, billets and blooms, which are used for the making of ready-made steel products through casting, rolling, pressing, forging, cold drawing.

Recycling of cast iron

Recycling of cast iron in steel is possible by melting but since it is an iron alloy of relatively high content of carbon and other undesirable elements are present in its composition, it melts and undergoes additional processing to remove excess carbon and other unwanted alloys, and in some cases, alloying elements are added. By itself, cast iron is also recycled by simpler processes of melting and re-casting.

In conclusion

Recycling of ferrous metals is a high-tech process that is based on the work and the aspirations towards progress of generations of scientists. Stepping on their shoulders today, we have the opportunity to contribute not only for the next step in improving technology, but more importantly, to take care of nature by recycling waste from our lives and activities.