Activities of NORD Holding

Nord Holding is an established name in the field of secondary raw material recycling.

The company was founded in 1995 by Borislav Malinov (majority shareholder and Chairman of the Supervisory Board).

Nord Holding is specialized in the collection and recycling of secondary raw materials and scrap, including:

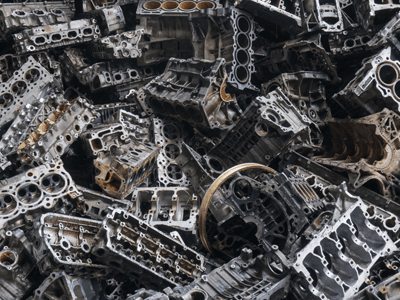

Waste ferrous metals

We buy any type of waste ferrous metal at premium rates. We provide assistance in transporting large quantities.

Learn more about our activities

Waste non-ferrous metals

At our scrap yards across the country we buy any type of waste non-ferrous metal, offering attractive rates. Contact us for an offer.

Learn more about our activities

Waste stainless steel

We buy stainless steel waste from households and the industry. Hand your waste stainless steel over to us to get the best price.

Learn more about our activities

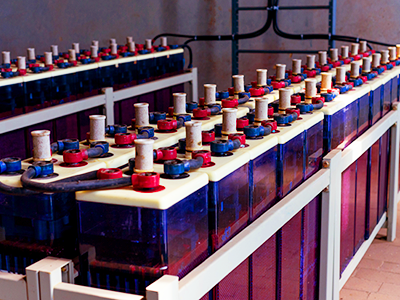

Automobile batteries

The best prices for waste lead-acid car batteries and lead batteries for UPS in Bulgaria! Call us for your quote!

Learn more about our activities

Cars, trucks and buses (ELVs)

The best way to get rid of an unwanted car is to scrap it. Besides money, you will receive all the documents required to delist the vehicle from the Traffic Police register.

Learn more about our activities

Waste oils

We collect waste oils for a fee with our transport in the cities of Sofia and Burgas. Plus we provide the documents required for their environmentally friendly recovery. Contact us for a quote.

Learn more about our activities

Collection of hazardous waste

We collect hazardous waste such as packaging containing residues of, or contaminated with, hazardous substances, absorbents and filter materials, brake fluid, antifreeze, lamps. Contact us for details.

Learn more about our activities

End-of-life tires (ELTs)

We collect end-of-life tires for a fee on your part.

We guarantee the subsequent recycling and recovery of end-of-life tires.

Learn more about our activities

Electric and electronic equipment (WEEE)

We buy all types of household electric equipment, large and small appliances, computers, printers, mobile phones, tablets, etc.

Learn more about our activities

Waste portable and industrial batteries (WBA)

We accept a variety of portable and industrial batteries. Best prices for lead-acid industrial batteries!

Learn more about our activities

Waste textile and footwear (textile waste)

We collect footwear and textile waste for a fee on your part. Contribute to reducing waste in the country!

Learn more about our activities

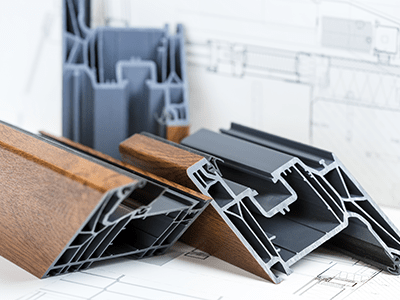

Waste PVC joinery

We accept and pay the best prices for PVC joinery – windows and doors – from households, as well as pieces from PVC joinery production.

Learn more about our activities