Ecology and recycling of metals

Ferrous and non-ferrous metal scrap is a valuable raw material for the recycling industry. This group of waste includes technological waste derived from the extraction, processing or machine treatment of ferrous and non-ferrous metals and their alloys, machinery, equipment and structures, metals from the construction and demolition of buildings, and metals of a household nature resulting from people’s living activities. In general, metals are also formed in the treatment of other waste streams as well, such as: end-of-life vehicles, electrical and electronic equipment, batteries and accumulators.

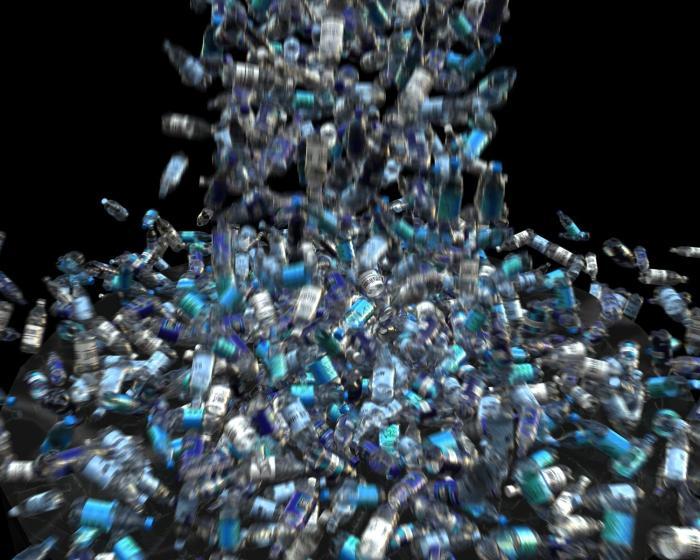

Recycling of metals involves several stages such as sorting, cutting, compacting and melting. When recycling metals, it is of great importance to pre-sort metal scrap. There is a network of metal waste reception sites in our country, but a significant part of them is mixed with the general waste stream and transported for landfill. The large companies operating in this sector provide a full range of services for the reception and subsequent treatment of metal scrap and metal containing waste until it is transported to final recyclers.

Recycling of metals has an invaluable benefit to ecology and economy. Recycling of metal scrap leads to solving an environmental problem associated with the accumulation of metal waste at waste sites and landfills, which occupy hundreds of hectares of useful land. We do not even think what this or that item is made of, we just use it and, when it becomes unfit for use, we just throw it in the garbage.

If we look around, we can see how many metal scrapes end up on the street every year, loads of construction waste, rusty iron, rotten cars, and household appliances in the city or outside the urban area, accumulate and become corroded or end up in landfills.

Dozens of years, centuries will be necessary for the metal disposed of in a landfill to break down. Metals decompose extremely slowly, and in the oxidation process some elements in the composition of technical alloys form toxic salts. Metals such as tin, lead, zinc, cadmium and others are released which are capable of destroying human health, accumulate in plants and in the bodies of farm animals, enter into ground and underground waters.

Mercury containing components are in themselves a great danger. Landfilling of metal containing waste without attempting to recycle is extremely wasteful and irresponsible towards future generations. No less damaging are the abandoned and corrosive metal structures – the rust in the form of dust forms and releases iron oxides, which are dangerous for the growth of plants. When entering salt water, the process of decomposition accelerates. Metal ions are retained in the soil and pose a health hazard if crops are grown on these soils.

Waste recovery centers, metallurgical plants carrying out the actual final recycling and foundries melting scrap are the ones that can solve the metal waste problem. The extraction of metals from secondary raw materials has benefits to many leading industries.

Metallurgical and machine-building enterprises experience a shortage of quality raw material. Metal scrap, in terms of its technical and quality characteristics, is in no way inferior to primary raw materials. Secondary metal production has a much simpler technological and production cycle. Almost every metal can be subjected to secondary melting, which significantly saves the cost of extracting the metal from the ore and processing it.

Metal ores are a non-renewable natural resource and the time will come when the ore deposits on the planet will be exhausted. According to experts, the known reserves of some ores are almost exhausted, while the exploration and development of new deposits requires huge investments accompanied by high risk.

The extraction of metals from ores and their subsequent treatment causes great damage to the environment. The development of a minefield is associated with a radical change in the chemical composition of vast quantities of rock and earth masses. In the process of processing the ore, toxic wastes form which are directly released into the atmosphere.

The solution to the problem is the use of secondary raw materials in the metallurgical industry. To date, about half of the produced steel is produced from second-cycle raw materials – ferrous metal waste.

All metals can be recycled indefinitely, with minimal quantitative losses and full retention of their technical properties. The recycling of metal scrap, as compared to ore mining, has the following advantages: it reduces the value of the finished metal 2 ÷ 4 times; reduction in the amount of ore extracted for the needs of the metallurgical industry; reduction in energy consumption; reduction in the emissions of carbon, sulfur and nitrogen oxides and other potentially dangerous compounds; reduction in the consumption of other resources, in particular water and oxygen.

Recycling of metal waste allows for a 40% reduction in raw material consumption, reduces the waste disposal area and the need to recultivate the terrains on which landfills are located.

In addition to saving natural resources, secondary processing of metals helps to reduce the environmental impact of the metallurgical industry. The melting of steel from scrap reduces the consumption of mineral raw materials (1 ton of cast iron or steel scrap can save 3.5 tons of mineral raw materials: 2 tons of iron ore, 1 tons of coke and 0.5 tons of limestone), thus reducing the harmful emissions in the atmosphere.

Modern metallurgical aggregates and new technologies enable recycling that produces metal products with much better technical characteristics than those produced in primary processing.

What is of utmost importance, however, is how much of the metals at the end of their life cycle are actually recycled and how much of them are lost in landfills. Existing assessments show that over 80% worldwide is the degree of recycling of titanium and chromium only.

Iron is 80%. Then follow 13 metals (silver, aluminum, gold, cobalt, copper, manganese, niobium, nickel, lead, palladium, platinum, rhenium, rhodium, tin, and zinc) with a recycling rate of over 50%. Below 50% is the recycling rate of magnesium, molybdenum, tungsten, cadmium, ruthenium and iridium.

In the age of global consumption of products, the recovery of valuable raw materials from industrial and household waste is particularly important. What will we leave to the next generations – fresh air, water and soil or mountains of waste? Pollution and irrational use of raw materials reduces the ability of future generations to have living resources and to be healthy.